Discover the fusion of tradition and innovation in lathe manufacturing. In this blog, we unveil how panel computers and touch screens, combined with cutting-edge Industrial Monitors, are redefining efficiency and precision in a timeless industry. Join us to explore real-world applications, insights, and expert analysis, empowering lathe professionals and enthusiasts alike. From enhancing control to simplifying operations, we’ll dive into the transformative potential of technology on the shop floor. Whether you’re a machinist, shop owner, or simply curious, this journey promises to illuminate the future of lathe manufacturing. So, let’s embark on this exciting quest to streamline lathe manufacturing with modern technology.

Introduction

Introduction to Lathe Manufacturing

Lathe manufacturing is a timeless craft, dating back centuries, renowned for its precision and versatility. Craftsmen have long relied on lathes to shape raw materials like metal, wood, and plastics into intricate, cylindrical forms. In this blog, we’ll explore how the age-old art of lathe manufacturing has seamlessly integrated with modern technology, specifically focusing on the game-changing impact of Panel Computers and Touch Screens.

The Importance of Technology in Modern Manufacturing

In today’s manufacturing landscape, technology is the driving force behind innovation and efficiency. Traditional craftsmanship, like lathe manufacturing, has evolved to meet the demands of the modern era. Automation, computer-aided design (CAD), and robotics have revolutionized the industry, making precision and productivity more achievable than ever before. It’s within this context that Panel Computers and Touch Screens have emerged as indispensable tools, elevating the precision and control of lathe processes.

Blog Focus: Panel Computers and Touch Screens in Lathe Manufacturing

Our blog is dedicated to uncovering the transformative role of Control Panels and Interactive Displays in the realm of lathe manufacturing. We’ll delve deep into their applications, exploring how these cutting-edge technologies have become integral components of the industry. From enhancing control to simplifying complex operations, we’ll demonstrate how Panel Computers and Touch Screens are revolutionizing lathe manufacturing, ushering in a new era of precision, efficiency, and user-friendly interfaces. Join us on this journey as we unveil the future of lathe manufacturing through the lens of modern technology.

Understanding Lathe Manufacturing

Basics of Lathe Machines in Manufacturing

Lathe machines are the unsung heroes of manufacturing, essential for crafting precision components across industries. These machines operate on a simple yet ingenious principle: rotating a workpiece while a cutting tool removes material, resulting in symmetrical, cylindrical shapes. Their role in manufacturing is multifaceted, from producing intricate parts for aerospace to crafting everyday objects. Now, imagine enhancing this age-old process with the power of modern technology—Panel Computers and Touch Screens.

Challenges in Lathe Manufacturing and the Role of Panel Computers and Touch Screens

While lathe machines are a cornerstone of manufacturing, they come with their share of challenges. Precision, paramount in this field, demands meticulous control and error-free execution. Efficiency, too, is a constant pursuit to meet growing demands. This is precisely where Panel Computers and Touch Screens step in as catalysts for transformation. These cutting-edge technologies address these challenges head-on, providing intuitive control interfaces and real-time data insights, elevating lathe manufacturing to new levels of precision and efficiency.

By seamlessly integrating Panel Computers and Touch Screens into the world of lathe manufacturing, we unlock a realm of possibilities where precision meets technology, and efficiency becomes the new standard. Join us as we explore how these innovations are shaping the future of manufacturing, redefining what’s possible in this age-old craft.

The Role of Technology in Lathe Manufacturing

Historical Context of Technology Adoption in Lathe Manufacturing

Lathe manufacturing has a rich history that mirrors the evolution of technology. From the earliest hand-operated lathes to the advent of steam power and electric motors, innovation has always been at the core of this industry. Over time, lathe machines evolved, becoming more automated and precise. However, it’s in the modern era, with the integration of cutting-edge technologies like Panel Computers and Touch Screens, that we witness a transformative leap in lathe manufacturing capabilities.

Current Trends and Innovations Reshaping Lathe Manufacturing with Panel Computers and Touch Screens

In today’s fast-paced manufacturing landscape, staying ahead means embracing the latest trends and innovations. One of the most significant trends is the widespread adoption of Panel Computers and Touch Screens in lathe manufacturing. These technologies are enabling manufacturers to achieve levels of precision and efficiency that were once unimaginable. From intuitive control interfaces to real-time monitoring and data analytics, Control Panels and Interactive Displays are revolutionizing the way lathes operate, making them more versatile, accurate, and user-friendly.

Panel Computers: A Game-Changer

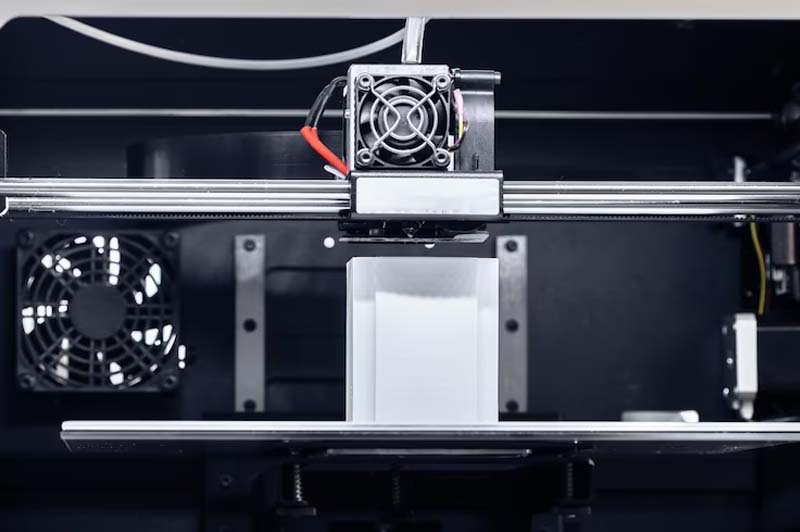

Defining Panel Computers and Their Applications in Manufacturing

Panel computers, within the realm of manufacturing, are sophisticated devices equipped with integrated touch screens. These robust machines serve as the nerve center of modern industrial processes. Their applications span a wide spectrum of functions, from overseeing production lines to monitoring data in real-time. Panel Computers and Touch Screens are instrumental in revolutionizing manufacturing, offering precise control, automation, and seamless interaction with complex machinery.

The Transformation of Lathe Manufacturing Through Panel Computers

In the context of lathe manufacturing, Panel Computers and Touch Screens have ushered in a transformative wave. Traditionally, lathe operations required manual adjustments, constant monitoring, and a significant margin for human error. However, the integration of these technologies has elevated precision and control to unprecedented levels. Operators can effortlessly set parameters, monitor progress, and make real-time adjustments with a simple touch. This shift has not only enhanced efficiency but also substantially reduced the likelihood of errors, making lathe manufacturing more precise and productive than ever before.

Real-World Use Cases: Demonstrating the Power of Panel Computers and Touch Screens

To truly grasp the impact of Panel Computers and Touch Screens in lathe manufacturing, let’s explore some real-world examples. In the aerospace industry, these technologies have revolutionized the production of intricate components, meeting stringent precision requirements. Likewise, in the automotive sector, lathe manufacturing powered by Control Panels and Interactive Displays has streamlined the production of vital engine components, ensuring consistency and quality.

Touch Screens in Lathe Manufacturing

Introducing Touch Screen Technology and Its Industry Relevance

Touch screen technology has transcended the realm of consumer electronics and found a crucial place in industrial settings, including lathe manufacturing. Its relevance in the industry is driven by the need for intuitive and efficient control interfaces. Touch screens provide a user-friendly means to interact with complex machinery, transforming the way operators manage lathe processes. In this blog, we’ll explore how the adoption of Panel Computers and Touch Screens is reshaping lathe manufacturing by offering cutting-edge user interface solutions.

Advantages of Touch Screens in Enhancing User Interface and Control

The advantages of touch screens in the context of lathe manufacturing are substantial. These intuitive interfaces simplify complex control systems, reducing the learning curve for operators. With a touch, operators can access real-time data, adjust parameters, and monitor progress effortlessly. This level of user-friendly control enhances precision, reduces the potential for errors, and ultimately boosts efficiency. The integration of Display Screens and Control Interfaces empowers operators to take command of lathe machines with ease and confidence.

Showcasing Specific Touch Screen Solutions for Lathe Machines

Touch screen solutions designed for lathe machines cater to the specific needs of the industry. They offer ruggedness to withstand the demands of industrial environments, ensuring durability and longevity. Additionally, these solutions come in various sizes, enabling flexibility in integration based on machine requirements. Whether it’s a compact lathe or a large-scale industrial system, Touch Panel Computers and Screen Displays can be tailored to fit seamlessly, enhancing both the user experience and the overall efficiency of lathe manufacturing operations.

Streamlining Lathe Manufacturing

Streamlining Processes with Panel Computers and Touch Screens

Panel Computers and Touch Screens have become pivotal tools in the manufacturing landscape, streamlining processes in myriad ways. Their intuitive interfaces simplify complex tasks, reducing the need for extensive training. Operators can swiftly access vital data, adjust settings, and monitor progress in real time. This seamless interaction between humans and machines not only enhances control but also significantly streamlines manufacturing processes. From setup to operation, Screen Panels and Interactive Monitors offer a user-friendly experience that optimizes workflow.

Benefits of Improved Precision, Efficiency, and Reduced Downtime

The adoption of Panel Computers and Touch Screens translates into a host of benefits for manufacturing. Improved precision ensures that every product meets exacting standards, reducing costly errors and rework. Enhanced efficiency means faster production cycles, which is particularly vital in meeting tight deadlines. Reduced downtime is another significant advantage; these technologies enable proactive maintenance, minimizing unexpected stoppages and ensuring consistent productivity. In essence, Panel Computers and Touch Screens are catalysts for higher quality, quicker turnaround, and increased uptime.

Success Stories and Case Studies: Transformative Impact

Real-world success stories and case studies abound, showcasing the transformative impact of Touch Panel Computers and Screen Displays. Companies across industries have embraced these technologies to achieve remarkable results. From aerospace firms producing complex aircraft components with unparalleled precision to automotive manufacturers streamlining engine component production, the evidence is clear—Panel Computers and Touch Screens are game-changers. These technologies are not limited to large corporations; even small-scale businesses benefit from improved efficiency and higher product quality. These success stories illustrate that the adoption of Screen Panels and Interactive Monitors is a strategic move towards staying competitive and achieving manufacturing excellence.

Conclusion

In the world of manufacturing, we gotta keep up with the times. Panel Computers and Touch Screens are game-changers in lathe manufacturing, making it slicker than ever. They’re like the magic wand that brings precision, efficiency, and reduced downtime to the party.

Whether you’re crafting rocket parts, tuning up engines, or doing some hands-on work in a garage, these gadgets level up your game. Real-life success stories? We’ve got ’em. These tools aren’t just cool; they’re the secret sauce for top-notch manufacturing.

So, as we wrap this up, remember, the future is bright. With Panels and Touch Screens, you’re not just machining parts; you’re crafting a manufacturing masterpiece. Keep innovating!