A Programmable Logic Controller, or PLC, is a ruggedized computer used for industrial automation. These controllers can automate a specific process, machine function, or even an entire production line.

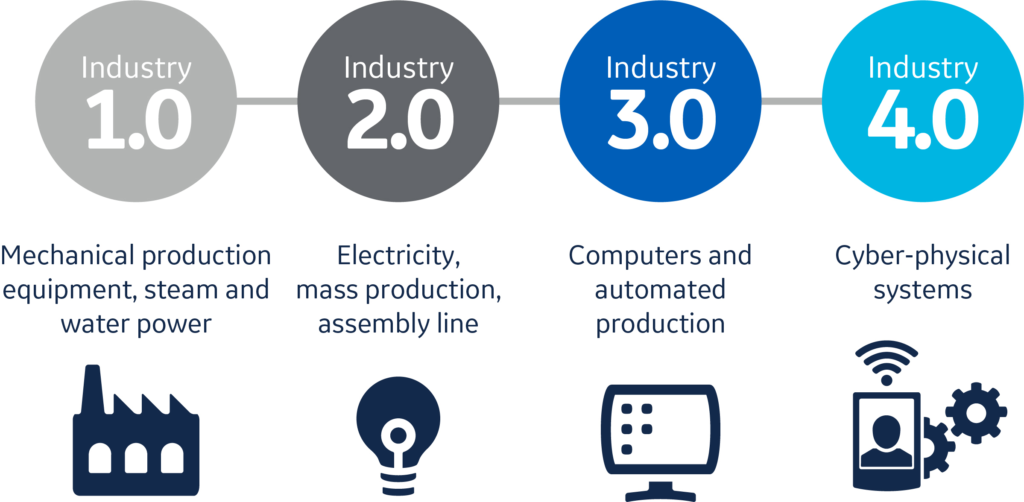

PLC is usually applied in SCADA and DCS systems as an important underlying control component to realize the specific operation and process control of industrial equipment, and is an important basis of the industrial control system. In the industrial site, because it is closest to the underlying industrial equipment, the industrial control system hardware and software system plays a vital role in the process of promoting intelligent manufacturing. As we all know, industry 3.0 refers to the electronic information age, that is, the wide application of electronic and information technology, so that the manufacturing process automation control degree is further greatly improved, from the 1960s to 1970s and has continued to the present. With PLC era, Industry 3.0 has become one of the most representative industrial products of Industry 3.0.

In January 1968, Bedford Associates developed a programmable controller that logic programming with trapezoidal graphs. In October of that year, Bedford Associates created the new company Modicon to promote the industrialization of the new programmable controller, with the new product named Modicon 084.

In November 1969, after learning of GM’s request, Dick Morley displayed the Modicon 084 for GM, and then used it to control metal cutting, drilling, material handling and assembly. Dick Morley is generally regarded as the “father of the PLC”.

In 1971, Allen Bradley engineers Odo Josef Struger and Ernst Dummermuth developed a new generation of controllers, model Bulletin 1774, named Programmable Logic Controller (PLC), with a dedicated programming terminal T3, which applied for U. S. patent US3942158. Odo Josef Struger later became an IEEE staff sergeant, vice president of technology at Rockwell, making significant contributions to Allen Bradley’s PLC architecture design and the development of national standards for PLC programming languages.

Reviewing the development history of PLC, its success is reflected in two aspects: one is to use the computer to analyze the past relay logic control; the other is to use the trapezoidal diagram logic programming, so that the original electrical engineering technicians can use computer programming based on their original technology.

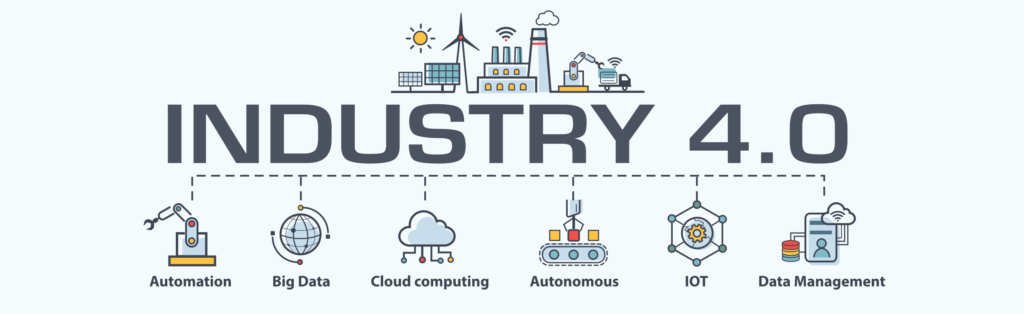

PLC is the product under the background of industrial economic development, which has brought an innovation to the field of industrial technology, makes programmable programs become the key to improve the operation efficiency of industrial production equipment, and plays an important role in promoting the actual industrial production. With the advent of the era of industry 4.0 and intelligent manufacturing, enterprises have higher requirements for production line automation, networking and intelligence. The biggest problem of PLC lies in its closed and dedicated characteristics. In the booming industrial Internet today, its closed and specificity, become the biggest resistance to the development of PLC.

Edge-programmable industrial controllers (EPIC) are becoming increasingly popular

Edge computing, as an important supplement to cloud computing, is paying more and more attention to its role in building connected factories. Edge computing realizes the data analysis, processing and storage at the network edge, which not only reduces the dependence on the cloud, but also improves the security of the data. However, the edge computing puts forward high requirements on the local processing capacity of the data, and the traditional PLC controller is no longer competent for such a work. In recent years, edge (EDGE) programmable industrial controllers (EPIC) are likely to replace traditional PC, servers, and legacy hardware in factory environments.

The Edge (EDGE) controller is designed to improve the efficiency of existing automation systems, while reducing complexity and cost of ownership, and can handle more automation features, including those traditionally required for PC or other dedicated devices. Edge controller can PLC controller, PC, gateway, motion control, I / O data acquisition, field bus protocol, machine vision, equipment networking and other functions integrated, at the same time realize the equipment motion control, data acquisition, computing and connected to the cloud, and on the edge side collaborative remote industrial cloud platform realize intelligent production line control, etc.

Where will PLC go?

The next generation of PLC architecture will be more open, distributed, with sufficient interoperability and the direction of internal information security, the software environment must be heavily absorbed and adopt open-source cloud computing software technology, and combined with the requirements and characteristics of industrial automation, thus out of a lasting vitality of the development of the road.

1. Networking. Networking and strengthening communication function is a key position of PLC development in recent years, which can be connected with several PLC control stations and several I / O architecture; which can be connected with industrial computer, Ethernet interface and MAP network, forming the automatic technology automatic control system of all processing plants.

2. High reliability. The credibility of automatic control system has gradually become the focus of engineering design industry. PLC has been self-confirmed technology, redundant technology, trial and error technology in current products, and many enterprises have released redundant systems with high reliability.

3. Multi-functionality. PLC has more and more functions, in order to integrate a variety of unique functions must be, in the original intelligent control module basically, various enterprises have released new program modules.

4. Miniaturization, low cost, simple and practical. Many enterprises have just begun to attach great importance to miniaturization, low cost, simple and practical system software. Many manufacturers that originally only produced medium, large and medium-sized PLC products are gradually releasing their products.

5. Integrated control and management functions. In order to realize the control and management of intelligent mass production must be necessary. PLC will generally choose the Internet solution technology, wireless communication network and graphic photoelectric technology, so that the PLC system software production control function and information management function are integrated.

6. Programming language develops to a high level. The programming language of PLC is constantly improving and developing to a high level in the original ladder diagram language, sequential platform language and command language. Soft PLC using PC programming technology has become more and more popular.

At the end, with the advent of 5G era, the development of PLC, cloud computing and edge technology, the traditional industrial control system is also constantly upgrading and changing. Based on the application of 5G cloud PLC technology, it will solve the problems of automation transformation, equipment digital management, information island phenomenon, lack of coordination between the front and rear industrial chain, low labor efficiency in the digital transformation of many enterprises, and achieve cost reduction and efficiency, and the application scenarios will be more and more extensive.

.jpg)