Background:

In today’s era of rapid technological development, the automobile manufacturing industry is undergoing a profound transformation with the level of automation & intelligence constantly increasing, and reshaping the landscape of automobile production.

As the global automotive manufacturing industry accelerates its transformation towards intelligence, flexibility and digitalization, the traditional production mode is facing huge challenges. Automobile manufacturing production lines need to meet increasingly complex production needs, including mixed-line production of multiple models, personalized customization, high-precision quality inspection, real-time data monitoring and equipment interconnection. At the meantime, the rise of Industry 4.0, the Internet of Things (IoT) and artificial intelligence (AI) technologies have promoted the upgrade of automobile manufacturing to “intelligent manufacturing”. In this background, industrial computers (IPCs) have gradually become the core control and data processing platform of automobile smart manufacturing production lines with their high-performance computing capabilities, environmental adaptability and system scalability.

Project Description:

The two themes of Industry 4.0 are smart factory + smart production. Automobile manufacturers generally adopt intelligent production management systems to achieve comprehensive monitoring and management of the production process. Through the Internet of Things technology, production equipment, sensors and control systems can be connected in real time to achieve data collection and transmission. The production management system can analyze and process this data, discover problems in the production process in a timely manner, and take corresponding measures to make adjustments.

It is MES system to help the automobile industries, which can automatically arrange production tasks according to the production plan and equipment status, optimize the production process and improve production efficiency. At the same time, the quality monitoring system can monitor the quality data of the production process in real time, such as dimensional accuracy, welding strength, coating quality, etc. Once a quality problem is found, an alarm will be issued immediately so that it can be handled in time.

What TAICENN do?

The intelligent MES system can realize real-time monitoring and management of the entire intelligent production process, optimize process management, reduce losses, and improve the efficiency and reliability of the assembly line in automobile industries.

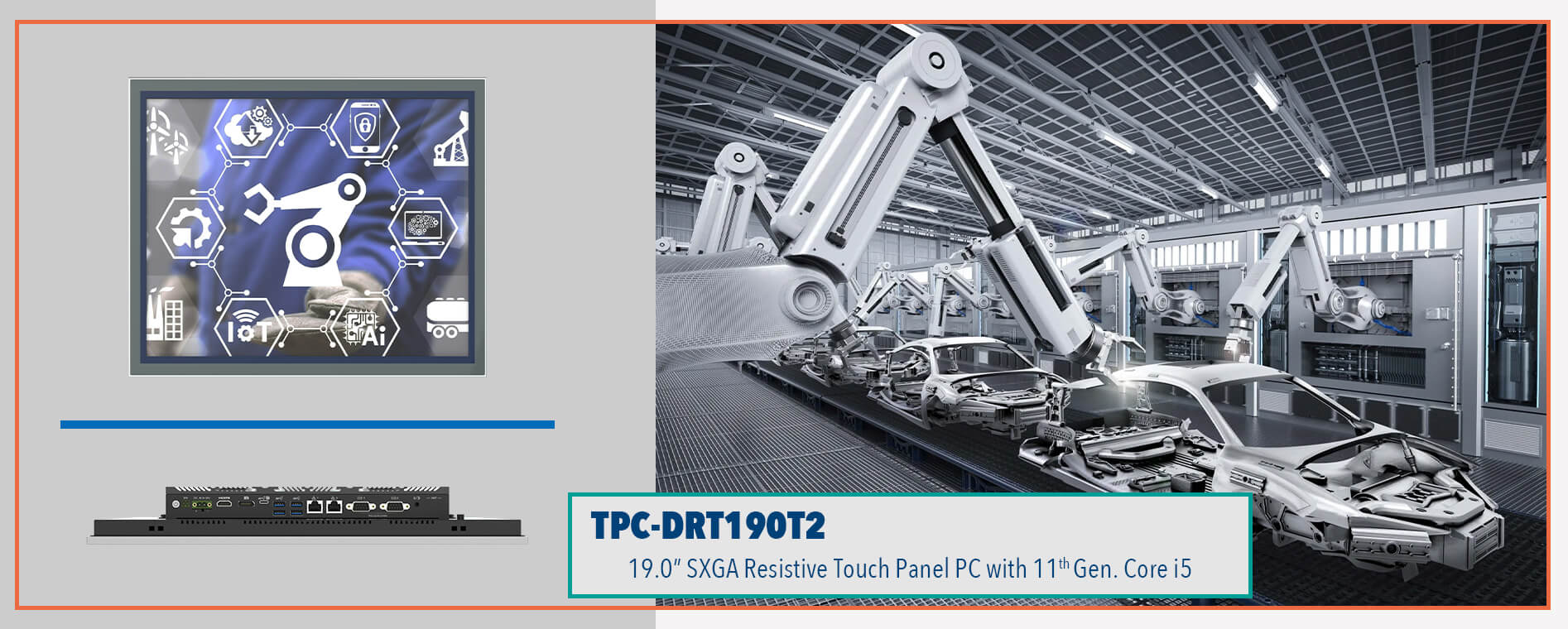

After our detailed consultant with customer, TAICENN offer a 19.0” SXGA 1280*1024 touch Panel PC TPC-DRT190T2 model for their project. It is a ruggedized, fanless & cableless design with 19.0″ SXGA LCD display and resistive touchscreen that’s to provide the most stable and reliable product solution for industrial HMI applications. This touch Panel PC is powered by Intel’s 11th Gen. Intel Tiger Lake UP3 SoC Core i5-1155G7 processor for power-efficiency performance. The integrated Intel Iris Xe Graphics built with innovative GPU architecture are able to optimize image and video handling capabilities. The TPC-DRT190T2 industrial resistive touch HMI embedded system support TPM2.0 (PTT2.0) and Windows 11 Operating systems, and 2* M.2 high speed and 1* Mini-PCIe expansional modules to supports Wi-Fi/BT, 3G/4G, and 5G cellular connectivity. It’s an ideal Panel PCs solution with abundant IO connections for MES system and SCADA system of intelligent manufacturing line of automobile industries.

What’s more, Taicenn Panel PCs are all modular concept designed & manufactured, we can ensure the less modification and changes to fulfill long-term supply and future upgrade process, which is very important to keep the stability of the whole production line of automobile industries.

Product Images for reference:

Product features:

● 19.0” TFT LCD display, LED Backlit, SXGA 1280 *1024;

● Intel 11th Gen. Tiger Lake UP3 Core i3/i5/i7 processors;

● 2* DDR4 memory, up to 64GB, 1* M.2 2280 (NGFF) storage;

● High precision 5-wires resistive touch, EETI controller;

● Aluminum-magnesium alloy, anodized treatment, Modular designed; ● Wide DC 9~36V power input range;

● IO: 2*GLAN, 2*USB3.1, 2* USB3.0, 2*COM (DB9), 1*HDMI, 1*DP, Audio;

● 1* USB-Type C (USB3.1 & DP1.4a), 1* SW Remote Switch;

● Intel PTT TPM2.0, support Windows 11;

● Fan-less & Slim design, Panel mount, VESA, Front IP65 protection.

At last:

The degree of automation and intelligence in automobile manufacturing has reached a high level and will continue to develop in the future. The application of new technologies will further improve the efficiency, quality and sustainability of automobile manufacturing, bringing new opportunities and challenges to the development of the automobile industry.