Automation is one of the critical fields to increase factory throughput and reduce costs for the manufacturing industry. And, the manufacturing sector is always looking for new and better ways to process raw materials and assemble products. For people like manufacturing managements, automation engineers, and IT technical staff, understanding the difference of PLC and industrial PC is a very important of maintaining a competitive edge.

What is a PLC and an IPC?

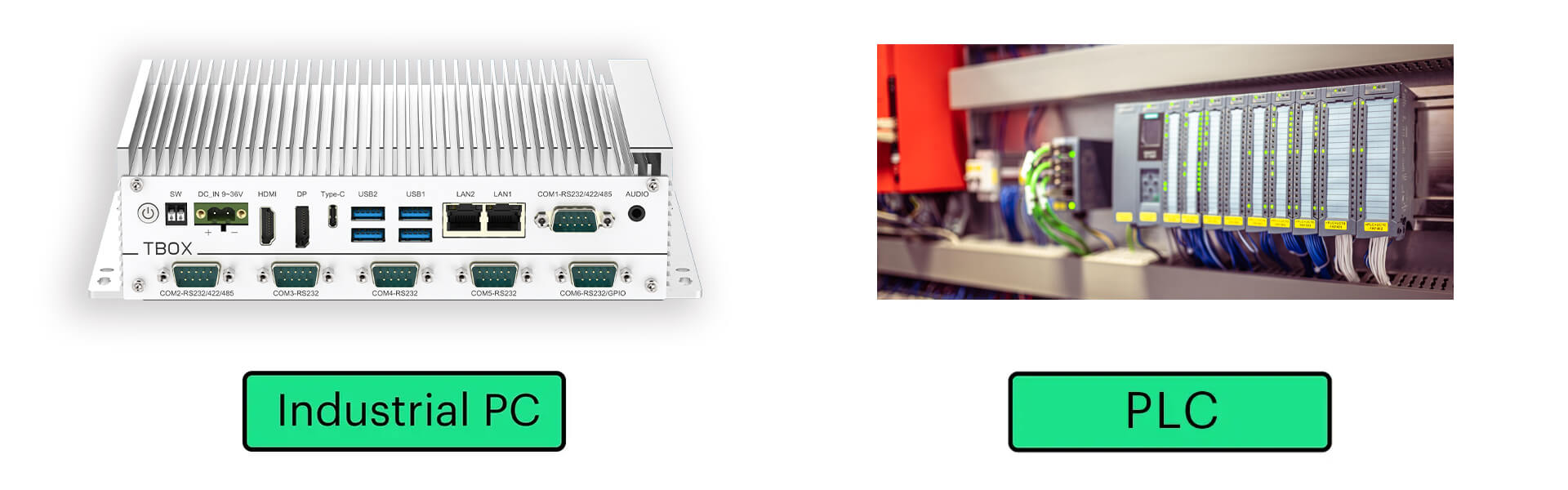

Programmable Logic Controller (PLC) is a specially designed industrial digital computer for controlling manufacturing processes. It is built to handle a multitude of inputs and outputs and are typically used for automation of machinery in industrial settings. PLC has a proprietary microprocessor and a unique Operating System, and is known for their robustness, reliability, and real-time performance capabilities. PLC is used in the automation of electromechanical processes, such as control of machinery on factory assembly lines, amusement rides, or lighting fixtures. Built to withstand harsh environments, PLC is programmed using languages like Ladder Logic, allowing PLC to be highly customizable for machine automation.

The development of computers (PCs) is increasing along with the exponential advancement of semiconductor chips. Industrial PCs are built and designed to withstand extreme environmental conditions, from extreme temperatures to shock and vibration exposures. Some designs and build materials that allow industrial PCs to be incredibly rugged are fanless designs, one-piece chassis, and industrial-grade materials. Moreover, industrial PCs are versatile used in factory automation, such as serial ports, COM, M12 connectors, DIO, GPIO, and many more. They offer more computing power and flexibility than PLCs, often running complex software for data acquisition, process control, and other demanding applications. While they can be used in similar environments as PLCs, their functionality and use cases can be quite different.

Difference between a PLC and an IPC?

To choose a PLC or an industrial PC, manufacturing management must consider performance metrics, programming capabilities, as well as the systems’ flexibility and scalability.

– Storage and Memory

One of the biggest limitations of PLCs is their lack of storage and memory size. Most PLCs only have enough memory to store their operating instructions for whatever their assigned task is.

On the other hand, industrial PCs can be equipped with big capacity of RAM and storage. This allows them to store and run complicated programs and handle a greater variety of responsibilities.

– Processing Power

One significant advantage of industrial PCs is that they are equipped with newest powerful CPUs that allow them to process and analyze greater amounts of operation data. This, in turn, lets them handle complex responsibilities, such as managing an entire assembly line rather than just a single machine on the line.

However, the microprocessors used by PLCs are far more basic and less powerful. While this makes them less expensive, it also makes them less capable in terms of raw computing power.

– Flexibility

Another aspect to consider about PLCs is that they are designed and programmed for a specific task and cannot easily be repurposed. A PLC in charge of an automatic gate system cannot be reused as an assembly line manager, for instance.

Industrial PCs use popular operating systems (OS) such as Windows or Linux to manage their applications. As long as the industrial PC has the correct software and I/O ports, it can be recognized by almost every device.

Summary – Industrial PC vs PLC

Both PLCs and industrial PCs have their applications in industrial automation. PLCs are ideal for smaller, specific automation tasks due to their ruggedness, cost-effectiveness, and security. Industrial PCs are better for complex applications requiring high computing and big memory & storage capabilities. They offer lower total cost of ownership for complex tasks and are secure with modern cybersecurity measures. To lots of automation projects, a combination of both can balance costs and benefits, depending on the manufacturing process needs.

Taicenn Technology: a leading global IPC Manufacturer

TAICENN, is a leading global provider and manufacturer of industrial panel PC, industrial display and industrial& embedded PC products, which are designed specifically for systems and applications that require excellent performance, high-level reliability and stability, long supply period and supports. Taicenn offers a wide range of industrial PCs tailored specifically for your industrial automation applications, including all-in-one Panel PC or fanless Box PC ranges. All our industrial PCs are modular concept designed & manufactured, rigorously tested, and validated for industrial projects.