Background:

Urban rail transit system refers to the urban rail transit system mainly operated underground, namely subway, subway and underground. Many of these systems were designed to accommodate the built environment and may be converted into ground or elevated roads outside the city center, considering construction and operational costs. Metro is a priority of a proprietary, high-density, high-capacity urban rail transit system (Metro), covering areas underground and above the city, known as rapid transit. With the increasing population of cities, the problem of traffic congestion has become the crux of urban development. Underground railway is exactly one of the solutions to this problem. Subway is the fundamental way to solve the public transportation of large and medium-sized cities, which is of great significance to realize the sustainable urban development in the 21st century.

It generally takes 3 to 5 years to open to traffic, among which the construction time of civil engineering is 2-3 years, mainly in the station construction and underground track construction. After the completion of the civil construction, only about 40% of the workload has been completed, including the equipment single debugging, system joint adjustment, station decoration, especially the total signal-based joint adjustment is very complex. After the system commissioning, the train runs without load. During the period, the reliability and safety of each equipment system were tested, trained, fault simulation and emergency drill. The trial run shall not be less than three months, followed by acceptance, acceptance and trial operation cross-over. All the information in the test run should rely on monitoring so that the engineers can fully understand the operation of the subway and deal with emergencies.

Application requirement analysis:

The project is used at a subway construction site that will be put into no-load trial operation. Because the test run is near, if the monitoring system is not complete, the next phase is not allowed. On the surface, the subway comprehensive monitoring system is a relatively simple system, but in the actual operation process, the impact of the system covers almost every part of the subway operation. The design scheme focuses on the advancement, reliability, flexibility and the long-term planning, considering the system scalability, business expansion function and system upgrade function.

TAICENN TBOX-3E10:

TAICENN discussed with end-user face to face, support on the site, to provide a best solution and product for the project. The TBOX-3E10 is a newest fan-less industrial Box PC model, specially designed for machine vision, industrial network applications. It adapts newest Intel Elkhart Lake Celeron J6413 Quad-core CPU, having advanced computer and graphic performance and low power consumption. TBOX-3E10 storage can support 1 *M.2 M-key SATA SSD and 1* 2.5 inch SATA SSD or HDD; The design has a variety of communication interface, with 4* LAN ports (3*Support PoE), 2* USB3.0 ports, 4* USB2.0 port, 2* RS232 (Optional with 1* RS485), 32*GPIO; The power input is DC 9~36V voltage, and has over-current, over-voltage and reverse-polarity protection.

Model:TBOX-3E10

● Intel Elkhart Lake Celeron J6413 Quad-core processors;

● 1* DDR4 memory socket, max. up to 16GB;

● 1* M.2 M-key 2280 SATA SSD, and 1* 2.5” SATA Storage;

● Two independent displays: 1* HDMI, 1* VGA;

● DC 9~36V input, with over-current, over-voltage, polarity protection;

● 4* GLAN (3* PoE), 6* USB, 2*COM, 32* GPIO;

● 1* Mini-PCIe and 1* M.2 2230 E-key slots for wireless and modules expansion;

● Industrial -20 ~ + 70℃ operating temperature range.

At the end:

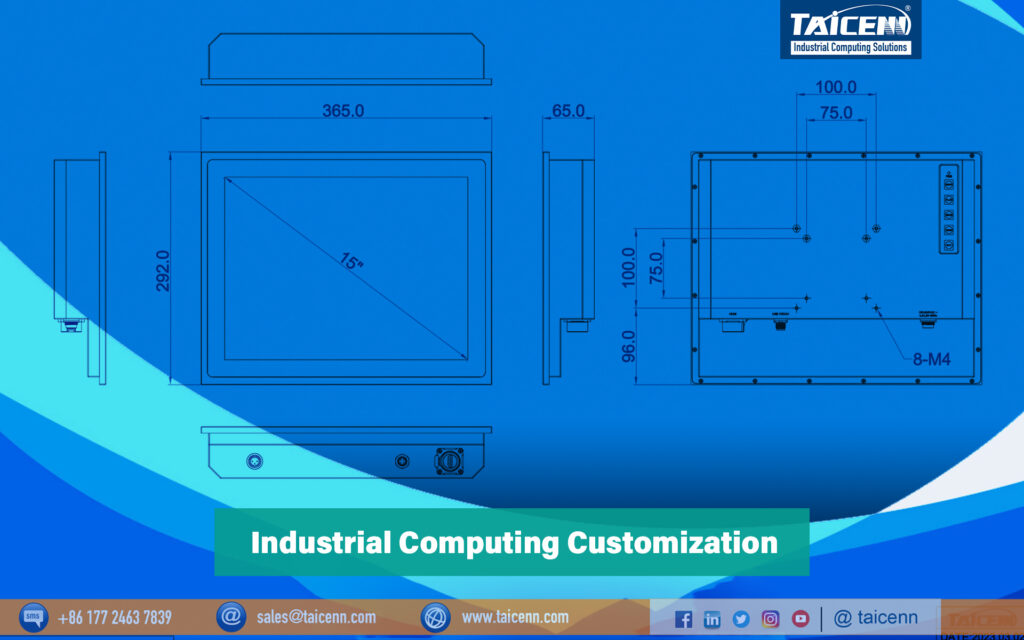

Sometimes, TAICENN standard products or slight modified solution products may not meet the requirement of customers’ applications, we still will evaluate each application project scientifically and rigorously, and provide customers with quick and flexible ODM & customize services. Our services can cover all our product lines, including industrial Box computers, industrial Panel PC and industrial monitors. Now, our ODM & customize solution products have been widely used in industrial IoT, industrial automation, commercial automation, smart factory, machine automation, machine vision, environmental and industrial facility monitoring, building automation, intelligent manufacturing and other related industries.