Background:

In the past few years,the COVID-19 outbreak,all walks of life are shrouded in an unspeakable repression,even some small and medium-sized enterprises have entered a desperate situation, in a word, less profits, high costs, how to use the least input for the maximum output, has become the top priority of some enterprises.For the weighing industry, the most people are on duty, which means the increase of labor costs, and the weighing process is cumbersome, and even some selfish people will cheat with each other, bringing immeasurable losses to the enterprise. If the unattended weighing system is selected, the above disadvantages will no longer exist. The most important thing is that it can realize data interconnection and sharing, and it can grasp the weighing dynamics anytime and anywhere through the mobile phone.

The Solution Scenario:

When the car enters the car weighing channel, the vehicle infrared positioning system installed at the intersection immediately senses a car entering, and transmits the signal to the front intelligent gate and traffic light prompt system. The gate is immediately closed, and the signal light turns red. Remind the driver to go slowly, and ask the scale and the reader to start working. When the electronic label on the vehicle enters the reading range of the reader, after verifying that the “vehicle identity” is legal, the control signal sends the correct signal indicating the electronic balance to start transmitting weight information, and uses the camera to monitor whether the vehicle is parked in a specified location and capture the image of the vehicle. The weighing signal can be accepted by the computer if the vehicle is parked properly. After receiving the ID number (corresponding to an identification code) and weight information, the host accurately records and backs up the relevant information; then sends the command to the controller, the relay on the controller moves, opens the gate, and the front traffic light turns green. Vehicles can exit the car lane. The host transmits the vehicle related information to the data management center, finally completes the data processing and statistics tasks, and then sends the data to the designated location through the local network.

Main functions of the unattended weighing management system:

1.You can automatically weigh, capture the image (mainly the license plate number) and video recording without the need for manual intervention (unless the machine or software fails, it can also be manually weighed).

2.When the data is query, the image of the weighing can be displayed on the interface when a record is clicked.

3.The corresponding car number, driver, goods name, supplier and receiving unit can be transferred automatically through the card number.

4.The room can be equipped with a large screen display to display the weighing weight, allowing the driver to see the weighing data.

5.The weighing method (primary or secondary weighing) can be set.If it is a weighing method, the system requires the leather weight be set in advance. When entering the car number, it can automatically call out the corresponding leather weight of the car number; if it is the second weighing method, print the pound sheet after the second weighing.

6.The system has multi-level operation permission management to prevent the original data from being changed by mistake. Only those who obtain the operation permission can change some important parameters. Only the superadministrator can modify the weighing data.

7.Image capture and video monitoring can be realized: when the car stops on the scale platform, the system will automatically save the weighing data and automatically capture the image, which can be used as the basis for future search.The image is monitored by the display.

8.Support manual weighing. In the unattended weighing failure, can be used to weigh, without affecting the weighing of the car.

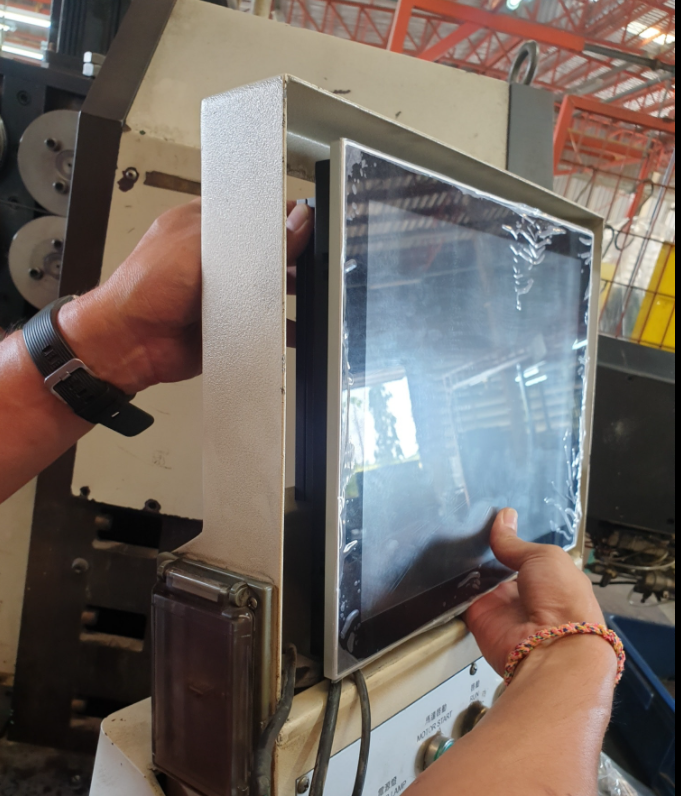

TAICENN Solution:

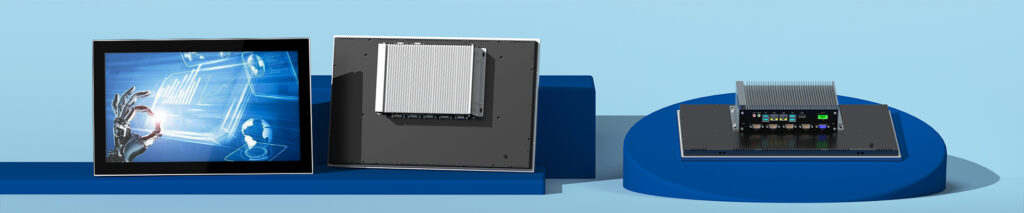

As a solution provider & manufacturer of industrial computing system, TAICENN constantly builds stable and reliable industrial computing hardware solutions based on market demand.

TPC-PC185HS series is a high performance, Fan-less designed, enhanced stability and reliability industrial 18.5-inch full HD 1920*1080 Touch Panel PC product. It adapts Intel Baytrail 6th –gen Core i3/i5/i7 processor. TPC-PC185HS series storage can support 2.5 SATA and mSATA interface, HDD or SSD. The design uses a multi-point (10- points) projective capacitive touch screen (Optional with high-temp. five-wires resistive touch, or No touch), and it can fulfill front panel NEMA/IP65 dust-proof and water-proof standards.

Model:TPC-PC185HS

● 18.5” TFT LCD display, LED Backlit, Full HD 1920 *1080;

● Intel 6th -gen. Skylake -U Celeron, Core i3/i5/i7, dual-core processor;

● Multi-points (Max. up 10 points) Projective capacitive touch, EETI controller;

● Aluminum-magnesium alloy, anodized treatment, Modular designed;

● DC 12~24V, with over-current, over-voltage and polarity protection;

● 2*GLAN, 6*USB, 6*COM, 1*HDMI, 1*VGA, Mic-in/Line-out;

● Fan-less & Rich IO design, Panel mount, VESA, Front IP65 protection.

At last:

As the data collection end of information management and control, intelligent hardware has a vital impact on whether the function of the management and control system is accurate and whether it can really play a role. For enterprises, through the intelligent weighing system can effectively improve the vehicle loading rate, make the vehicle profit maximization, at the same time facilitate managers remote real-time understanding of vehicle load dynamics and cargo loading time, place, to ensure the safety of goods, on time, real-time load, location information is clear at a glance, also bring customers more secure and convenient experience.

.jpg)