Industrial Mini computers have been widely used in various industries due to their small size and high computing capability, such as industrial automation, commercial automation, rail& transportation, municipal administration, factory automation, water treatment systems, and urban security, all kinds of smart applications, etc. However, due to the different on-site environment, various mounting methods are often used when installing industrial Mini computers, including desktop, wall-mount, VESA mount, and DIN-rail installation. Next, follow us and we will introduce these mounting methods of industrial Mini computers in detail, so that you can better replace the industrial computer!

1. Desktop mount

The industrial Mini computers can be placed directly on a smooth, flat, and safe desktop, which is also referred to as “desktop installation” for short. It must not only ensure that the working environment has a large enough space, but also ensure the ventilation and heat dissipation space of the equipment. At the same time, you need to pay attention to the following two points:

1) Ensure that there is a space distance of at least 3cm-5cm around the industrial Mini computers, and no heavy objects are placed on the top of the Mini computer;

2) Ensure that the physical surface of the industrial mini computers can bear a weight of more than 3kg.

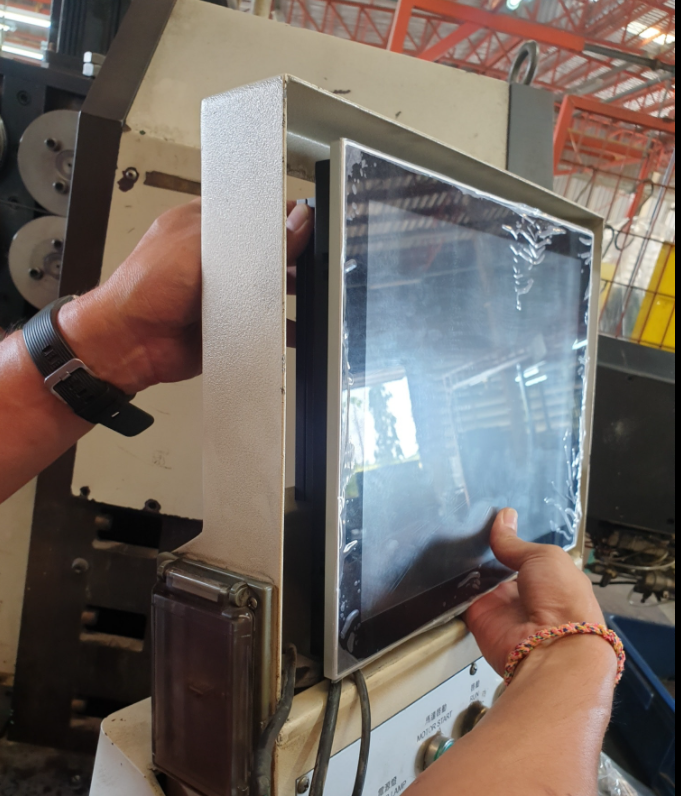

2. Wall-mount

The wall-mount installation of industrial minicomputers is very common in industrial field applications. We fix it with screws of the Industrial Mini Computer to the wall. We need to check whether the screws are fixed in place; Then fix it in the wall-hanging hole reserved on the wall-hanging ear.

3. VESA mount

Industrial mini computers are sometimes fixed in industrial or commercial automation applications through standard VESA 75/100 mount methods. Generally speaking, the industrial mini computers is designed with standard VESA holes, which can be fixed on the industrial application site through VESA rack and brackets.

4. DIN rail mount

The general industrial mini computers adopt standard DIN rail installation, which is very convenient in most industrial applications. The installation steps are as follows:

1) Check whether you have DIN-Rail rail installation tool accessories to ensure that everything is okay;

2) Then adjust the product to the correct direction, that is, the power terminal is upwards correctly;

3) Then clamp the upper half of the product guide rail (the part with the circlip) into the guide rail first, and then slightly force the lower half into the guide rail;

4) After clamping the DIN rail into the rail, check and make sure that the product is balanced and reliably fixed on the DIN rail.

TAICENN currently provides a wide range series of industrial minicomputers, which provides a great important role to the development of industrial automation and modern intelligence.

.jpg)