Industry 4.0 concept includes the basic mode change from centralized control to decentralized enhanced control. Its goal is to establish a highly flexible production mode of personalized and digital products and services. In this model, traditional industry boundaries will disappear, and various new fields of activity and forms of cooperation will emerge. The process of creating new value is changing, and the division of labor in the industrial chain will be reorganized.

Industry 4.0 projects are mainly divided into three main themes:

– The first one is the “smart factory”, focusing on the study of intelligent production systems and processes, and the realization of networked distributed production facilities;

– The second is “intelligent production”, which mainly involves the entire enterprise’s production logistics management, human-machine-interaction, and the application of 3D technology in industrial production processes. The plan will pay special attention to attracting the participation of small/medium sized enterprises, and strive to make small/medium sized enterprises become the users and beneficiaries of a new generation of intelligent production technology. At the same time, it become a creator and supplier of advanced industrial production technology;

– The third is “smart logistics”, which mainly integrates logistics resources through the Internet, the Internet of Things (IoT), and logistics networks to give full efficiency of the existing logistics resource suppliers, while the demand side can quickly obtain service matching and logistics support.

The core of industry 4.0

The meaning of the Industry 4.0 is the fourth industrial revolution in human history. The first industrial revolution was the mechanization of factories through hydraulic and steam engines that started from the 1860s to the mid-19th century; the second industrial revolution was the widespread use of electricity from the second half of the 19th century to the beginning of the 20th century; the third industrial revolution was the production process automation based on programmable logic controller (PLC) that appeared in the second half of the 20th century. So, the positioning of Industry 4.0 is a technological innovation comparable to these industrial revolutions.

The essence of Industry 4.0 is to use data flow automation technology to build a heterogeneous customized industry at the cost of homogenization and scale. This is a vital role for the reform of the industrial structure.

Industry 4.0 drives a new round of industrial revolution, and the core is interconnection. Internet technology reduces the information asymmetry between production and sales, and accelerates the interconnection and feedback between them. Therefore, it has spawned a consumer-driven business model, and Industry 4.0 is a key link in realizing this model. Industry 4.0 represents the intelligent production of “Internet + manufacturing”, bred a large number of new business models, and can truly realize the “C2B2C” business model.

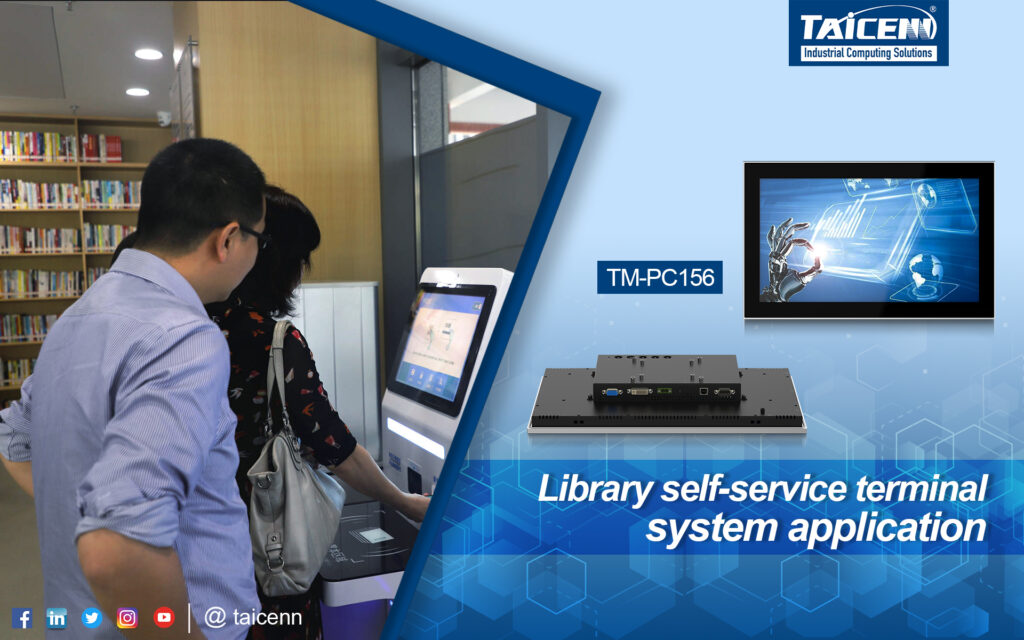

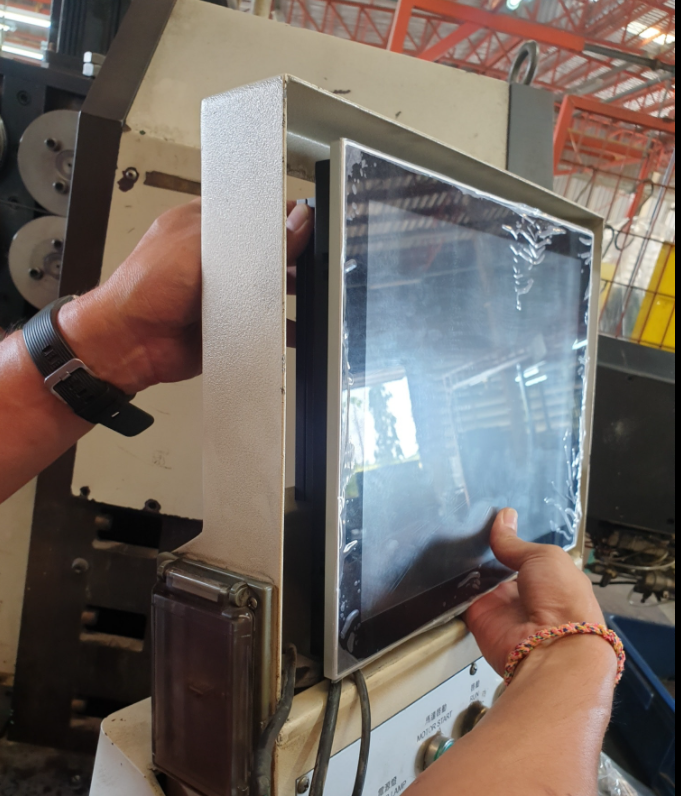

Regarding the upcoming trend of data flow automation, the world’s major manufacturing powers have different understandings. As a core part of industry 4.0 sector fields, Industrial computers have been using more and more popular, providing high performance computing power for industry 4.0.

If you are looking for industrial computers, industrial Panel PC products line for industry 4.0 projects, Taicenn might be a good solution provider & manufacturer to support. www.taicenn.com

.jpg)