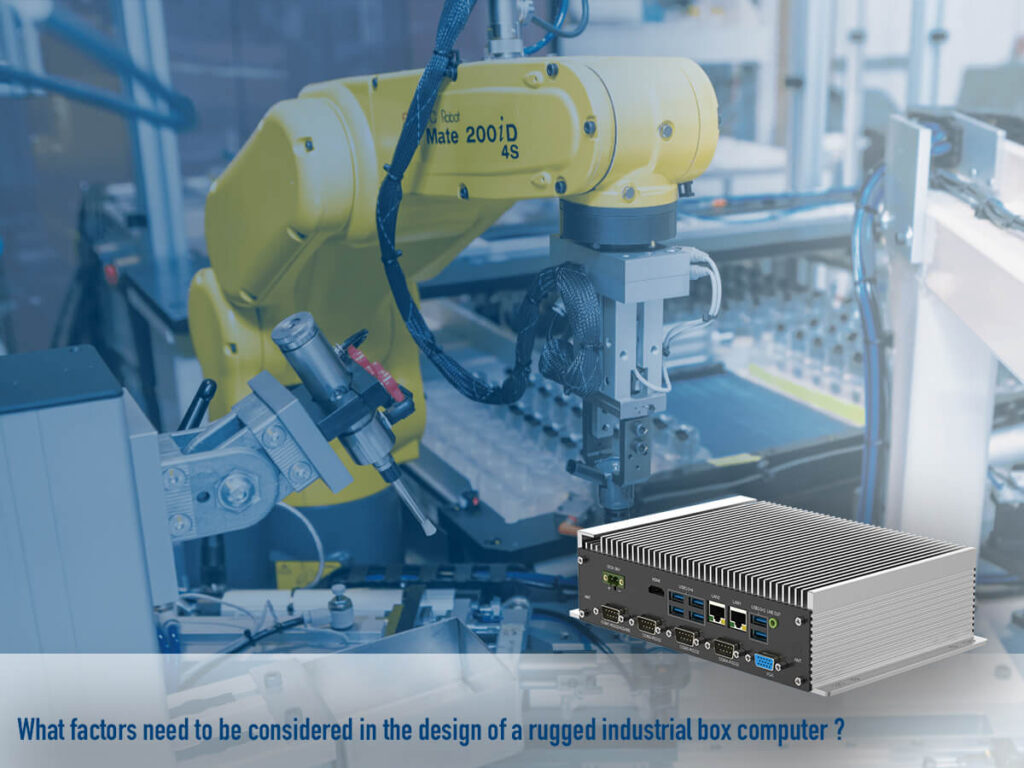

The industrial automation field environment is complex, such as vibration, high/low temperature, electromagnetic interference, and humidity…etc. The complicated application environment sometimes may damage the industrial computer and cause the failure of the entire application system. The structure of the rugged industrial box computer is extremely sturdy and durable, and can withstand extreme environments including tough shock and continuous vibration, long-term durability, reliability and service life.

Six factors considered in the design of a powerful rugged industrial box computer:

1. Fanless design

The rugged embedded industrial box PC adopts a fanless design and uses passive cooling to effectively dissipate heat from internal components to the external environment. The heat sink conducts heat from the computer’s hottest CPU processor and dissipates it through the outer housing for cooling. Fanless design is an extremely important aspect of choosing a rugged industrial box PC.

2. Solid state drive (SSD) storage

Due to fragile rotating disks, mechanical hard disk storage is one of the most vulnerable components to be damaged by shock and vibration. When the disk is running very fast, a slight jitter on the computer may cause data corruption and some faulty functions that increase the risk of downtime. The SSD do not rely on any moving parts, and its data store on a series of NAND memory chips with no vibrating parts. Using chips instead of mechanical parts, the SSD storage makes the read/write performance better and faster. the storage effect is very reliable, which is very suitable for a rugged industrial box computer system.

3. Industrial components

Powerful reinforced industrial box PC requires advanced design and high-quality components &materials. The reinforced industrial computer is made of industrial-grade IC components, including resistors, capacitors, power chips, high-quality PCBs, I/O terminals, etc. The design of a rugged industrial computer requires stable and reliable industrial-grade components to ensure long-term operation and supply.

4. All-in-one metal chassis

In order to ensure that the rugged industrial box computer to withstand the harshest application environment during the deployment process, the housing of the industrial box PCs is generally made of an all-in-one metal chassis. The all-in-one metal chassis can also be used as a heat sink, dissipating heat from internal components. Since there are fewer joint parts, gaps and screws, the sealed enclosure can prevent dust from entering, and to increase the level of protection during deployment.

5. Comprehensive testing and verification process

In order to ensure the quality of rugged industrial box computers, the industrial computers must undergo detailed testing and verification to ensure reliable MTBF performance. The testing and verification process is carried out in a reliable testing facility that tests the limits of the equipment under every possible environmental situation.

TAICENN utilizes our modular design and manufacturing concepts, and aim to be a solution provider & manufacturers of industrial computing hardware, providing industrial computing solutions and products for complex industrial automation and various types of automation applications. TAICENN industrial computers product can meet the complex field environment of industrial applications and help the implementation of industrial automation.