Introduction

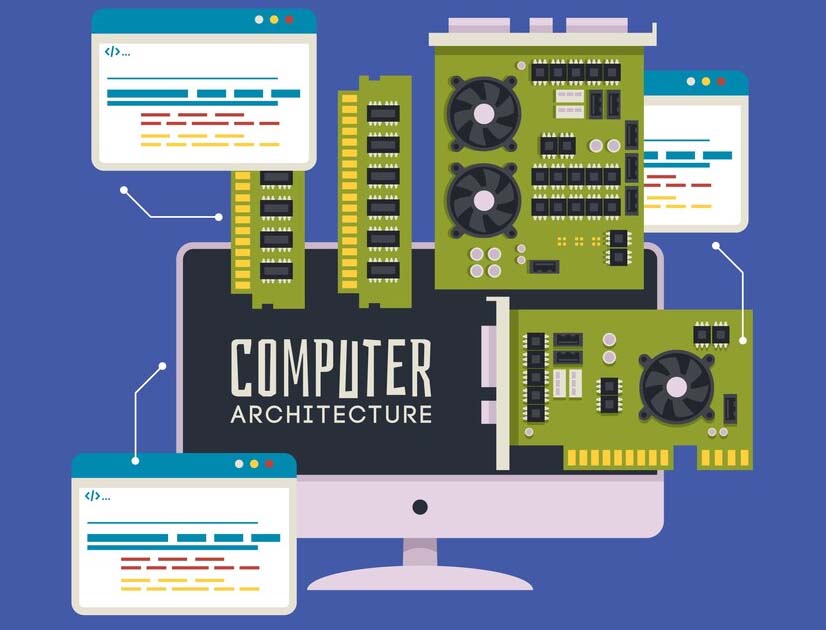

In the ever-evolving landscape of technology, the demand for robust and reliable computing solutions has led to the rise of industrial-grade PCs. These specialized computing systems play a crucial role in powering the backbone of industries, offering unparalleled performance and durability. In this blog post, we delve into the world of industrial-grade PCs, exploring their features, applications, and the impact they have on various sectors.

What Sets Industrial-Grade PCs Apart?

Industrial-grade PCs, often referred to as rugged computers, distinguish themselves from their consumer counterparts through a series of key features that make them suitable for demanding environments. These systems are designed to withstand harsh conditions such as extreme temperatures, vibrations, and humidity, ensuring uninterrupted operation in industrial settings.

Durability and Robustness

Manufacturers build industrial-grade PCs to withstand the rigors of challenging environments. These PCs often have ruggedized casings, reinforced components, and adhere to specific industry standards for durability. This makes them ideal for applications in manufacturing plants, outdoor installations, and other environments where standard computers may falter.

Temperature Resistance

Conventional PCs might struggle in extreme temperature conditions, but manufacturers engineer industrial panel PCs to function reliably across a wide range of temperatures. Whether it’s scorching heat or freezing cold, these computers maintain their performance, making them indispensable in sectors like oil and gas, aerospace, and automotive manufacturing.

Vibration and Shock Resistance

Industrial settings, such as factories and construction sites, expose electronic equipment to constant vibrations and shocks. Manufacturers equip industrial-grade PCs with shock-absorbing mechanisms and reinforced components to ensure that these conditions do not compromise performance.

Dust and Moisture Protection

Many industrial applications involve exposure to dust, moisture, and other contaminants. Industrial-grade PCs often come with sealed enclosures and protective measures against ingress, safeguarding sensitive internal components from damage caused by environmental factors.

Applications of Industrial-Grade PCs

The versatility and resilience of industrial PCs make them indispensable in a variety of sectors. Here are some key applications:

- Manufacturing and Automation: Industrial-grade PCs play a pivotal role in controlling and monitoring automated manufacturing processes. Their robustness ensures continuous operation in factory environments, where dust, vibrations, and temperature variations are common.

- Energy and Utilities: In sectors like energy production and distribution, where equipment is often located in remote and challenging environments, industrial-grade PCs provide the computing power needed to control and monitor critical infrastructure.

- Transportation and Logistics: Rugged computers find applications in transportation and logistics, where they can withstand the vibrations and shocks associated with vehicles and ensure reliable operation in various climatic conditions.

- Military and Defense: Military operations demand computing systems that can withstand extreme conditions. Industrial panel PCs are designed to meet stringent military standards, making them suitable for deployment in defense applications.

Conclusion

As industries continue to advance, the demand for reliable and durable computing solutions will only grow. Industrial-grade PCs stand as a testament to the technological innovation required to meet these demands. Their robust design and resilience make them indispensable in sectors where standard computers would fall short. As technology continues to evolve, industrial panel PCs will likely play an increasingly pivotal role in shaping the future of industrial automation and control systems.