Industrial touch panels are interactive devices utilized in various industrial settings to facilitate control, monitoring, and visualization tasks. These panels serve as user interfaces that enable operators to interact with complex machinery, systems, and processes effectively. They play a crucial role in enhancing operational efficiency, productivity, and safety within industrial environments. From manufacturing plants to transportation systems and healthcare facilities, Industrial touch monitors have become indispensable tools for streamlining operations and ensuring smooth workflow management. Their intuitive interface and robust design make them ideal solutions for demanding industrial applications, where reliability and performance are paramount. As technology continues to advance, the role of industrial touch panels is poised to expand further, driving innovation and efficiency across diverse industrial sectors.

Understanding Industrial Touch Panels

Industrial touch panels encompass a spectrum of technologies designed to facilitate seamless interaction between humans and machines within industrial environments. These panels employ various sensing mechanisms to detect and respond to user input, enabling precise control and monitoring of industrial processes.

One of the most common technologies used in industrial touch panels is resistive touch technology. In resistive touch panels, a thin, flexible layer coated with conductive material lies over a glass or rigid substrate. When pressure is applied to the screen, the two layers contact each other, determining the coordinates of the touch point. Manufacturers value resistive touch panels for their durability and reliability, making them suitable for rugged industrial applications where harsh conditions may be present.

In contrast, capacitive touch technology is also widely utilized in industrial touch computer. Capacitive touch panels feature a glass overlay coated with a transparent conductor such as indium tin oxide (ITO). When a finger or stylus touches the screen, it disrupts the electrostatic field, enabling the detection of the touch point. Capacitive touch panels offer high sensitivity and responsiveness, making them ideal for applications requiring precise input control.

Furthermore, industrial touch panels come with a range of features and specifications tailored to meet the specific requirements of industrial environments. These features may include:

- High durability to withstand harsh operating conditions, such as extreme temperatures, moisture, dust, and vibrations.

- Enhanced visibility through features like high brightness, anti-glare coatings, and wide viewing angles to ensure optimal readability in varying lighting conditions.

- Multi-touch capabilities, allowing users to perform gestures such as pinching, zooming, and rotating for intuitive interaction.

- Compatibility with gloved or stylus input, enabling operation in environments where direct finger touch may not be feasible.

- Integration with industrial communication protocols such as Modbus, Profibus, or Ethernet/IP for seamless connectivity with industrial automation systems.

Applications of Industrial touch control panels

Industrial touch panels serve essential functions across various industries, enhancing operational efficiency, productivity, and user experience. Here are some key applications where Industrial touch display screens play a pivotal role:

Manufacturing and Automation

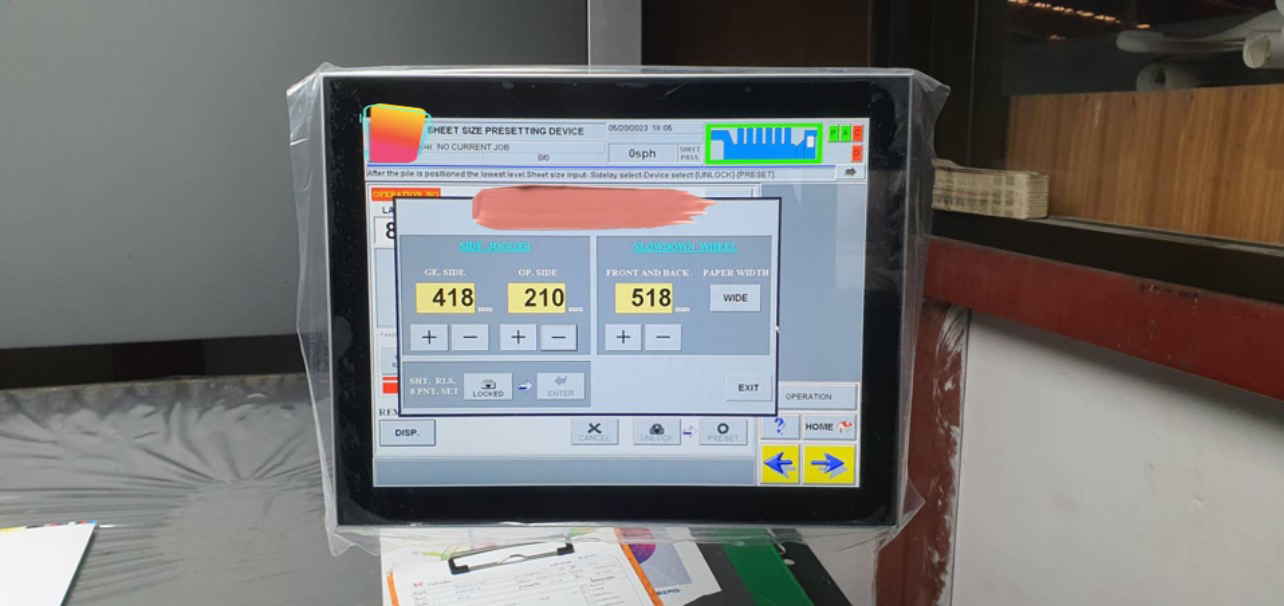

In manufacturing facilities, operators utilize industrial touch panels to control and monitor machinery, adjusting parameters and troubleshooting issues in real-time. These panels provide intuitive interfaces for process visualization, enabling operators to monitor production progress and identify bottlenecks efficiently. Additionally, Industrial touch control panels aid in quality control processes, empowering operators to input inspection data and analyze production metrics to ensure product consistency and compliance with quality standards.

Transportation

Industrial touch panels are integral components of vehicle control systems in transportation vehicles like trains, buses, and airplanes. They enable drivers and operators to interact with onboard systems, including navigation, engine controls, and diagnostics. Moreover, Industrial touch control panels serve as passenger information displays, offering real-time updates on routes, schedules, and safety information to travelers. Furthermore, these panels facilitate ticketing and fare collection, providing passengers with convenient self-service options for purchasing tickets and accessing transportation services.

Healthcare

In healthcare settings, medical professionals utilize industrial touch panels in medical equipment interfaces to control and monitor diagnostic and treatment devices effectively. These panels offer intuitive user interaction, allowing clinicians to adjust settings, input patient data, and access diagnostic results seamlessly. Moreover, caregivers integrate Industrial touch control panels into patient monitoring systems, utilizing them to deliver real-time vital sign data and alerts for timely intervention.

Retail and Hospitality

Industrial touch panels find applications in retail environments, powering point-of-sale terminals, self-service kiosks, and digital signage. At checkout counters, these panels enable cashiers to process transactions quickly and efficiently, enhancing customer service and reducing waiting times. Self-service kiosks equipped with Industrial touchscreen displays empower customers to browse products, place orders, and make payments independently, improving convenience and reducing staffing requirements. Furthermore, Industrial touchscreens drive digital signage displays, delivering dynamic promotional content and information to engage customers and enhance brand visibility.

Energy and Utilities

In the energy and utilities sector, operators rely on industrial touch panels for monitoring and controlling critical infrastructure such as power grids, renewable energy systems, and water treatment plants. These panels provide centralized interfaces for operators to monitor equipment status, analyze performance metrics, and respond to operational events promptly. By leveraging Industrial touchscreen displays, utility companies optimize energy generation and distribution processes, enhance system reliability, and ensure regulatory compliance.

Advantages of Industrial Touch Panels

Durability and ruggedness

Industrial touch panels are built to withstand harsh environments typically found in industrial settings. Constructed with robust materials and sealed enclosures, these panels are resistant to dust, moisture, and mechanical shocks, ensuring reliable operation even in challenging conditions. Their rugged design minimizes the risk of damage due to accidental impacts or exposure to environmental factors, resulting in long-term durability and minimal downtime.

Ease of operation

Industrial touch panels feature intuitive interfaces that simplify user interaction and minimize the need for extensive training. With touch-based controls and graphical user interfaces, operators can perform tasks quickly and efficiently, reducing human error and improving overall productivity. Additionally, the responsive nature of touch panels enables operators to execute commands with precision, enhancing operational control and effectiveness.

Space-saving design

Industrial touch panels are designed to optimize space utilization in cramped industrial environments. Their compact form factor and integrated display eliminate the need for separate input devices and bulky control panels, saving valuable floor space. By consolidating control and monitoring functions into a single panel,Industrial touchscreen displays enable efficient use of available workspace while maintaining accessibility and usability.

Enhanced efficiency and productivity

By providing real-time access to critical information and controls, industrial touch panels enable operators to make informed decisions and respond promptly to changing conditions. This enhanced situational awareness translates into improved operational efficiency, reduced downtime, and increased throughput. Moreover, features such as customizable interfaces and multi-touch support further enhance productivity by tailoring the user experience to specific workflow requirements and preferences.

Integration with other industrial systems

Industrial touch panels are designed to seamlessly integrate with other industrial systems, such as PLCs, SCADA systems, and MES. This interoperability enables data exchange and communication between different components of the industrial automation infrastructure, facilitating centralized control, monitoring, and data analysis. By leveraging integration capabilities, Industrial touchscreen displays contribute to the creation of interconnected and interoperable industrial ecosystems, enabling holistic management of industrial processes and assets.

Challenges and Considerations

Environmental factors

Industrial environments often expose touch panels to extreme temperatures, high humidity, dust, and vibrations. These environmental factors can impact the performance and longevity of touch panels, necessitating the use of ruggedized designs and protective enclosures to ensure reliable operation in harsh conditions.

Calibration and maintenance

Regular calibration and maintenance are essential to ensure the accuracy and responsiveness of industrial touch panels over time. Touch panel calibration helps maintain precise touch recognition, while routine maintenance, such as cleaning and inspection, prevents the buildup of dirt and debris that can affect performance. Implementing proactive maintenance schedules minimizes downtime and extends the lifespan of industrial touch panels.

Compatibility with existing infrastructure

When deploying industrial touch panels, compatibility with existing infrastructure, including hardware, software, and communication protocols, must be considered. Integration with PLCs, SCADA systems, and other industrial equipment requires careful planning and coordination to ensure seamless data exchange and interoperability. Compatibility issues can lead to inefficiencies and disruptions in industrial processes, highlighting the importance of thorough compatibility testing and validation.

Cost considerations

While industrial touch panels offer significant benefits, cost considerations are an important factor in the decision-making process. The initial investment in Industrial touch input panels includes hardware costs, software licensing fees, installation expenses, and ongoing maintenance expenses. Additionally, factors such as scalability, upgradeability, and total cost of ownership (TCO) should be evaluated to determine the long-term cost-effectiveness of industrial touch panel solutions. Balancing functionality with affordability is crucial to maximizing the return on investment (ROI) of industrial touch panel deployments.

Conclusion

In conclusion, industrial touch panels are essential tools in modern industrial settings, providing intuitive interfaces for controlling machinery and enhancing productivity. Their durability, ease of use, and integration capabilities make them indispensable for streamlining processes.